|

|

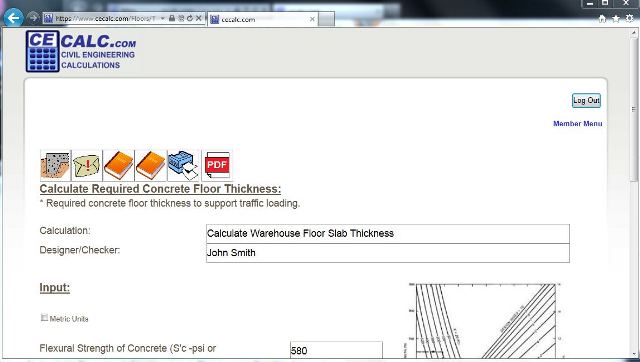

Concrete Floor Slab-on-Grade Design Problem 1 - Required concrete thickness:

|

|

Design a warehouse floor slab for an interior wall load of 1400 plf, stationary live load of 1200 plf, exterior wall load of 1000 plf and

an average daily volume of 25-15 kip forklift trucks per day using 4000 psi concrete and a modulus of subgrade reaction, k = 150 pci. |

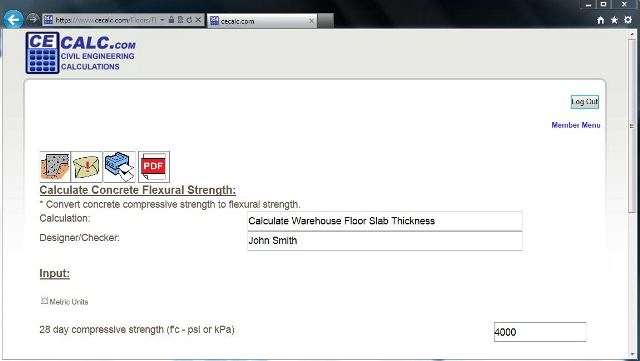

1. In order to calculate the floor load requirements the concrete compressive strength of the mix design will need to be converted to concrete flexural strength.

From the floors on grade submenu open the traffic loads concrete flexural strength calculation, FlexStrength.aspx. Input the "Title" of the calculation and the "Designer/Checker" information and the 28 day concrete compressive strength.

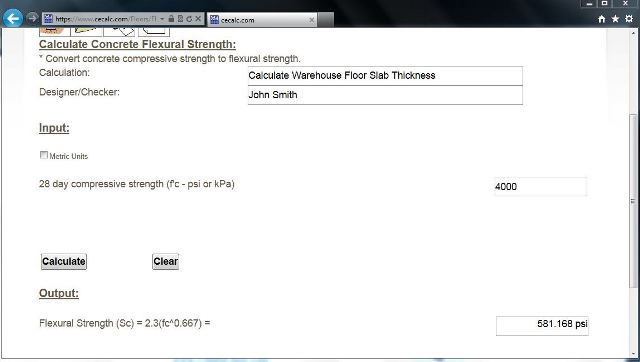

Click on the "Calculate" button and read the results. The concrete flexural strength is 581.168 psi. Use 580 psi.

|

|

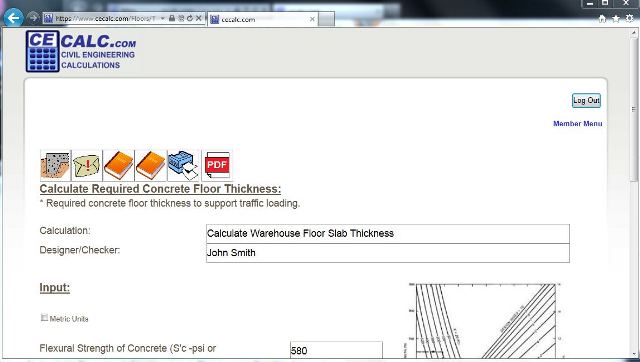

2. From the floors on grade submenu open the traffic loads concrete thickness calculation, TrafficConcTh.aspx. Input the "Title" of the calculation and the "Designer/Checker" information.

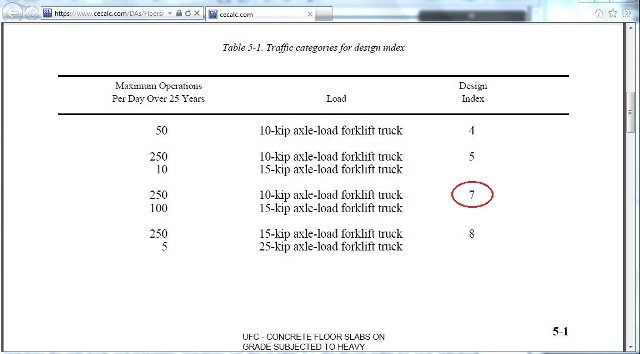

Open the design reference and go to table 5-1 to determine the design index. From the given traffic loading the DI = 7.

|

|

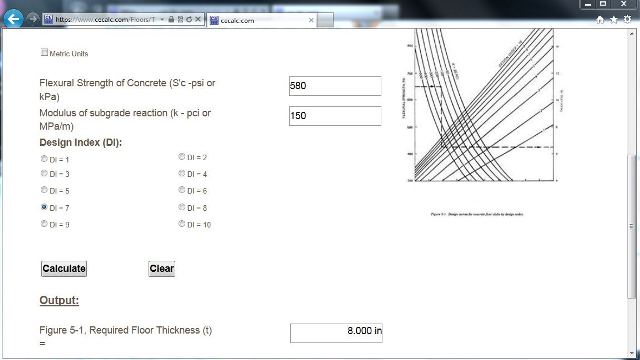

3. Now in the traffic loads concrete thickness calculation, TrafficConcTh.aspx, input the "Title" of the calculation, the "Designer/Checker" information and the calculated variables.

Click on the "Calculate" button and read the results. The required concrete thickness for traffic loading is 8 inches.

|

|

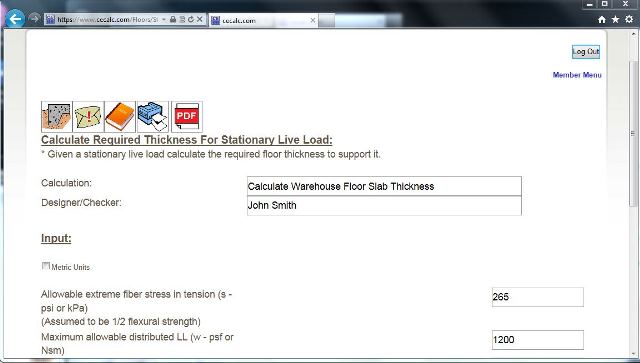

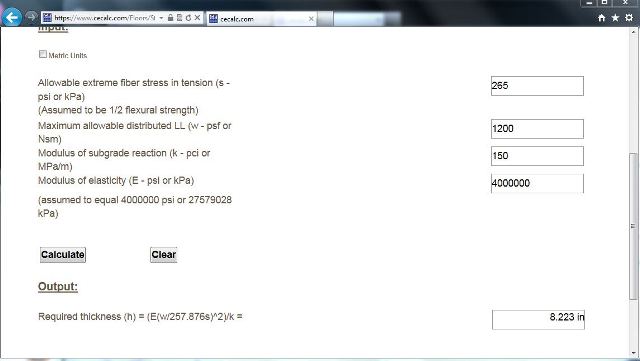

4. From the floors on grade submenu open the stationary live load concrete thickness calculation, StaLLTh.aspx. Input the "Title" of the calculation and the "Designer/Checker" information and the calculated variables.

Click on the "Calculate" button and read the results. The required concrete thickness for the stationary live load is 8.223 inches. Use 10 inches.

|

|

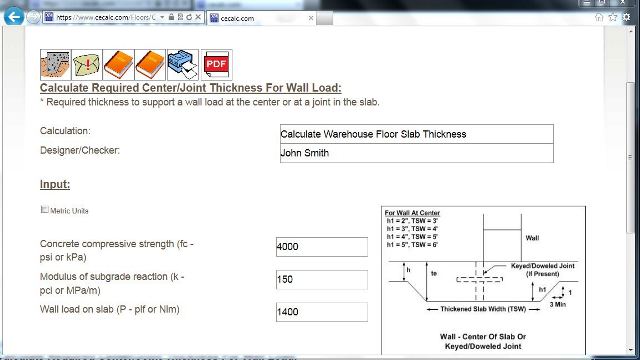

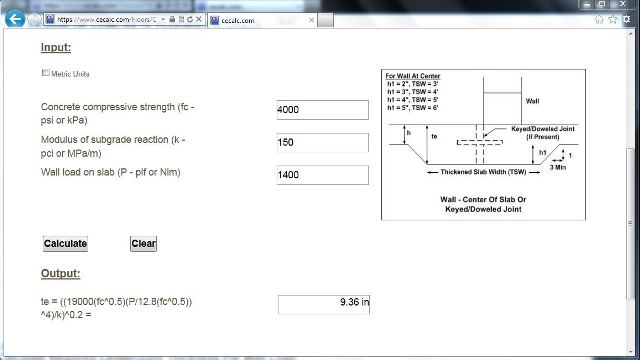

5. From the floors on grade submenu open the center wall load or joint concrete thickness calculation, CtrWallLdTh.aspx. Input the "Title" of the calculation and the "Designer/Checker" information and the calculated variables.

Click on the "Calculate" button and read the results. The required concrete thickness for the interior wall load is 9.36 inches. Use 10 inches.

|

|

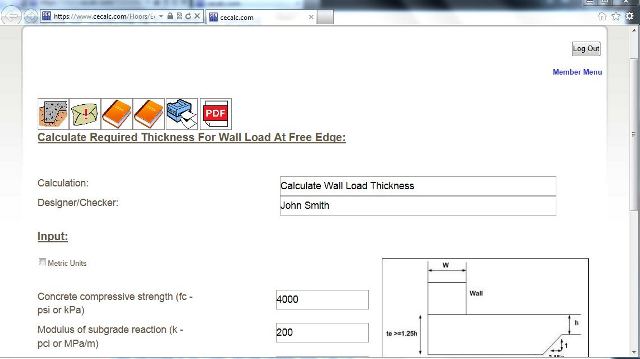

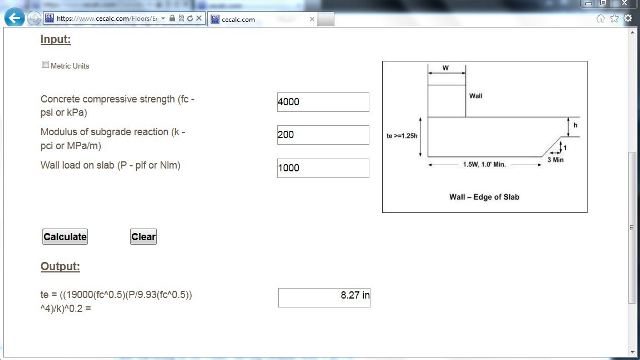

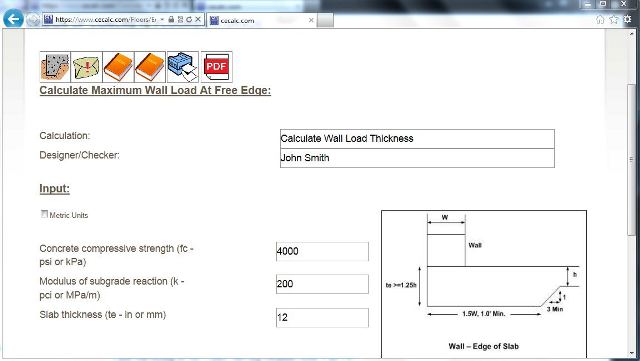

6. From the floors on grade submenu open the edge wall load thickness calculation, EdgeWallLdTh.aspx. Input the "Title" of the calculation and the "Designer/Checker" information and the variables.

Click on the "Calculate" button and read the results. The required concrete thickness for the edge wall load is 8.27 inches.

|

|

7. Typically concrete foundations including the thickened edge of a slab on grade must go below the frost depth for the area where it is constructed, with a minimum thickness of 12 inches required by the International Building Code, IBC.

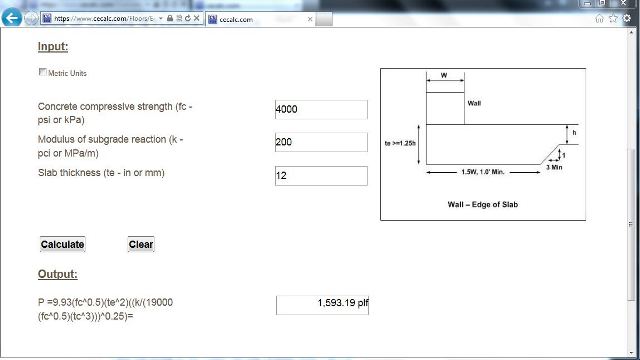

So if the IBC minimum of 12" depth is used, calculate the maximum edge load the thickened edge will support.

From the floors on grade submenu open the maximum edge wall load calculation, CtrWallLdTh.aspx. Input the "Title" of the calculation and the "Designer/Checker" information and the variables.

Click on the "Calculate" button and read the results. The maximum edge wall load for a 12 inch thickened edge is 1593.19 plf.

|

|

8. Summary

|

The floor slab should be 8 inches thick to support the traffic loadings, and should be increased to 10 inches under the stationary loading and under the interior wall loads.

The outside edge wall load requires only 8.27 inches in thickness, however the IBC minimum foundation depth is 12 inches which will adequately support a wall load of 1593 plf.

|

|

|