|

|

Steel Welds Design Problem 1 - Calculate Fillet weld size for a welded connection:

|

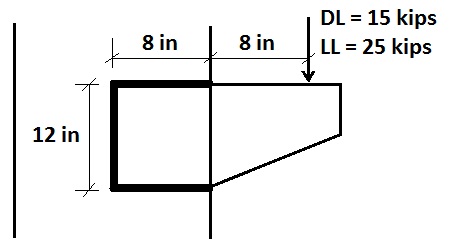

An eccentric load is applied to the flange of a W14 x 82 column as shown.

The bracket plate transfers the dead load = 15 kips and live load = 25 kips as shown.

What is the minimum weld size needed if E70XX electrode is used?

|

|

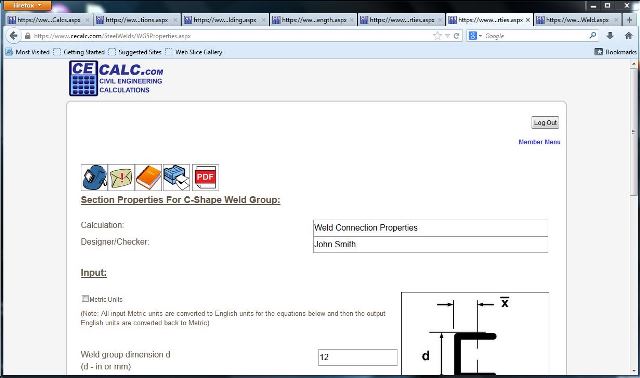

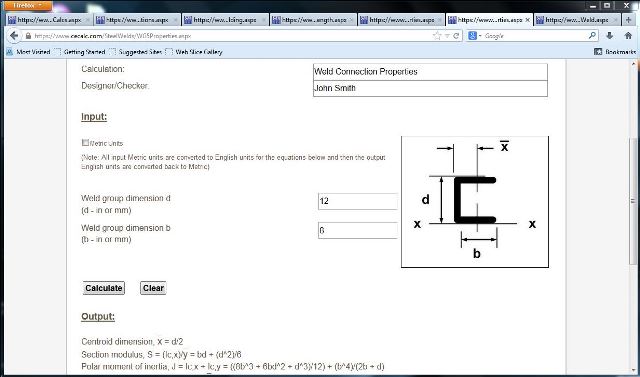

1. From the steel welds submenu open the weld group properties submenu and then open the section properties calculation for a C-shape weld group, WG5Properties.aspx.

Input the "Title" of the calculation, the "Designer/Checker" information, enter the variables and click on the "Calculate" button and read the results.

|

|

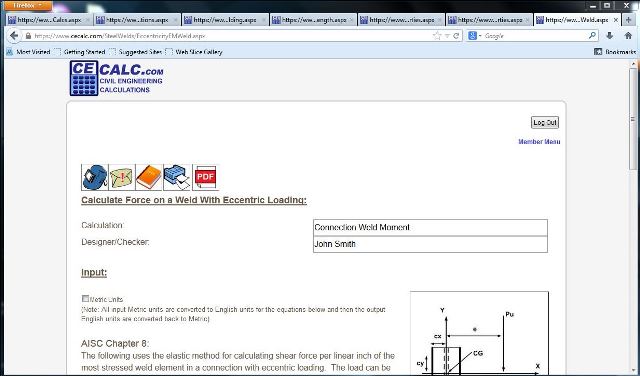

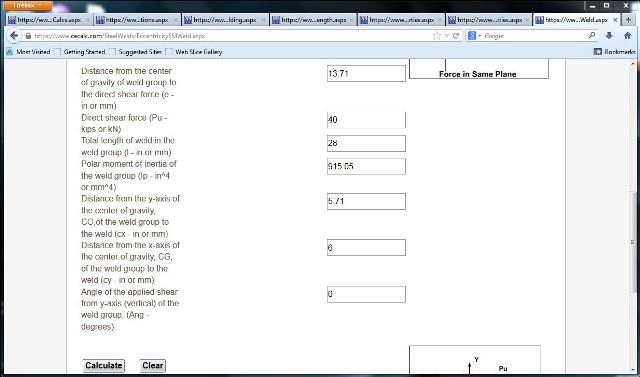

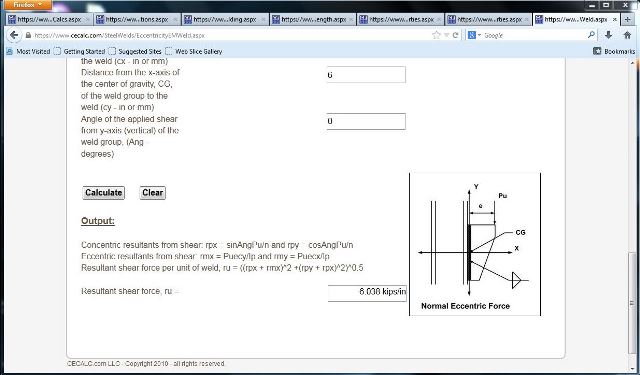

2. Next, from the steel welds submenu open the weld moment load calculation, EccentricityEMWeld.aspx.

Input the "Title" of the calculation, the "Designer/Checker" information, enter the variables, click on the "Calculate" button and read the results.

The resultant shear force, ru, on the weld is 6.038 kips/in. The required shear strength of the weld is 28(6.038) = 169.064 kips.

|

|

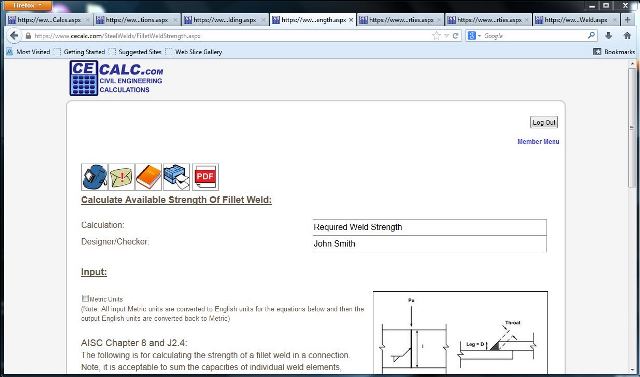

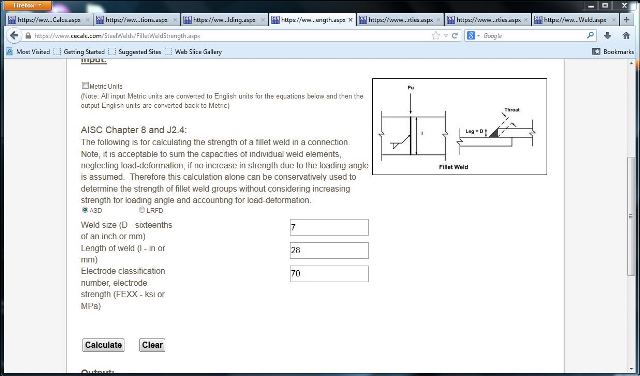

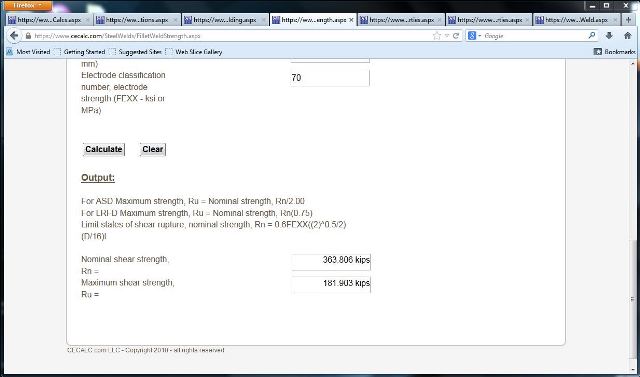

3. Finally, from the steel welds submenu open the fillet weld strength calculation, FilletWeldStrength.aspx.

Input the "Title" of the calculation, the "Designer/Checker" information and enter the variables. To start the trial and error check for strength, try a 7/16" weld.

Click on the "Calculate" button and read the results. The maximum shear strenth, Ru, of the weld is 181.903 kips which is greater than 169.064 kips.

|

|

4. Summary

|

Use a 7/16" fillet weld with a maximum shear strength, Ru, of 181.903 kips which is greater than the required shear strength of 169.064 kips.

|

|

|