|

Concrete Floor Design:

|

|

This design guide is intended to provide guidance for the safe design and economical

construction of suspended concrete floor slabs. This design guide and the corresponding

calculations are based on the requirements of ACI 318 and strength design method

where the capacity of the beam is designed to support factored loads.

Slabs are structural elements whose lengths and widths are large in comparison to

their thicknesses. Unlike beams, shear is generally carried by the concrete

without the aid of shear reinforcement. Longitudinal reinforcement is used

to resist bending moments. The slab thickness is typically governed by deflection

criteria or fire rating requirements.

|

Design of Two-way Slabs:

|

|

|

|

Slabs are defined as two-way slabs when the ratio of long-to-short sides is less

than 2. There are four types of two-way slabs. (a) A flat plate which is a

two-way slab supported on a column grid without the use of beams. (b) A flat slab

which is the same as a flat plate except the areas around the columns have increased

thicknesses, called drop panels, to increase the shear capacity at the columns.

(c) A waffle-slab which is similar to the flat plate except there are voids left

out in the areas away from the columns resembling a waffle. (d) Conventional slab

construction similar to the one-way slab with beams supporting the floor and resting

on top of columns.

|

|

Direct Design Method, DDM: The DDM can be used

when the following conditions are met: (a) There are a minimum of 3 spans. (b) Panels

are rectangular with a ratio of long-to-short side (center-to-center of supports)

of no more than 2. (c) Successive span lengths do not differ by more than one third

of the longest span. (d) Columns are not offset by more than 10% of the span in

the direction of the offset. (e) The loading consists of uniformly distributed gravity

loads. (f) The service live load does not exceed 2 times the dead load. (g) If beams

are present, the relative stiffness in 2 perpendicular directions is not less than

0.2 nor grater than 5.0.

|

|

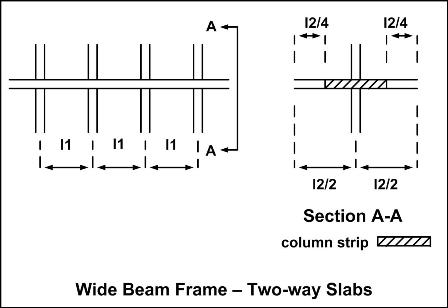

1. Divide the floor system in each direction into wide beams as shown below:

|

|

|

2. Calculate the total statical moment in each span as Mo = wul2ln^2/8. This

moment is the maximum moment in a simple beam of span ln that carries the total

load (wul2). In the equation the span l2 refers to the width of the wide beam

being considered. ln is measured face-to face of columns or other supports.

However, ln >= 0.65 l1. For the computation of minimum thickness in two-way

slabs, ln is taken as the distance face-to-face of supports in slabs without beams

and face-to-face of beams or other supports in other cases.

|

3. Divide the total moment, Mo, in each span into positive and negative moments.

For interior spans, the negative factored moment is calculated as 0.65Mo, and the

positive factored moment is 0.35 Mo. The total moment in end (exterior) spans

is distributed according to the coefficients in the table below:

|

Distribution of Moments in Exterior Spans

(fraction of Mo)

|

|

|

|

Slabs without

beams between

Interior supports

|

|

|

|

Exterior edge

unrestrained

|

Slab with beams

between

all supports

|

Without

edge

beam

|

With

Edge

beam

|

Exterior edge

fully restrained

|

|

Interior negative

factored moment

|

.075

|

0.70

|

0.70

|

0.70

|

0.65

|

|

Positive factored

moment

|

0.63

|

0.57

|

0.52

|

0.50

|

0.35

|

|

Exterior negative

Factored moment

|

0

|

0.16

|

0.26

|

0.30

|

0.65

|

|

|

4. Divide the width of the wide beam into column-strip and middle-strip regions.

A column strip is a design strip with a width of each side of the column centerline

equal to 0.25l2 or 0.25l1, which ever is less. A middle strip is a design

strip bounded by 2 column strips.

|

|

5. Design the column strip for the fractions of the moment at each section according

to the following table:

|

Distribution of Moments in Column Strips

(fraction of Mo)

(a is relative stiffness, Bt is the relative torsional

stiffness)

|

(a) Interior

negative moment

|

|

l2/l1

|

|

0.5

|

1.0

|

2.0

|

|

a1 l2/l1=0

(no beams)

|

|

0.75

|

0.75

|

0.75

|

|

a1 l2/l1 >=1

|

|

0.90

|

0.75

|

0.40

|

|

(b) Exterior

negative moment

|

|

l2/l1

|

|

0.5

|

1.0

|

2.0

|

|

a1 l2/l1 = 0

|

Bt = 0

|

1.00

|

1.00

|

1.00

|

|

a1 l2/l1 = 0

|

Bt >=2.5

|

0.75

|

0.75

|

0.75

|

|

a1 l2/l1 >= 1

|

Bt = 0

|

1.00

|

1.00

|

1.00

|

|

a1 l2/l1 >= 1

|

Bt >= 2.5

|

0.90

|

0.75

|

0.45

|

|

(c) Positive

factored moment

|

|

l2/l1

|

|

0.5

|

1.0

|

2.0

|

|

a1 l2/l1 = 0

(no beams)

|

|

0.60

|

0.60

|

0.60

|

|

a1 l2/l1 >= 1

|

|

0.90

|

0.75

|

0.45

|

|

The distribution of moments in two-way slabs depends on the relative stiffness of

the beams, a, with respect to the slab without beams. The relative stiffness,

a, is the ratio of the flexural stiffness of a slab of width equal to that of the

wide beam (i.e., the width of a slab bounded laterally by the centerlines of adjacent

panels).

a = EcbIb/(EcsIs)

where:

Ecb = moment of elasticity of the concrete beam

Ib = moment of inertia of the concrete beam

Ecs = moment of elasticity of the concrete slab

Is = moment of inertia of the concrete slab

|

The distribution of the negative moment across the width of a slab at the exterior

edge depends not only on the relative beam stiffness and the ratio l2/l1, but also

on the stiffness in torsion of edge beams.

Relative torsional stiffness, Bt = EcbC/(2EcsIs)

C = summ of (1 - 0.63(x/y))(x^3y/3) The summation is taken over all the separate

rectangles that make up the edge beam. The division into separate rectangles

that leads to the largest value of C should be used.

|

|

6. Design the middle strip for the fractions of the moment at each section not assigned

to the column strip.

|

|

Deflections in Two-Way Slabs:

|

|

To avoid calculating deflections in two-way slabs the slabs should be sized for

the following minimum thickness values:

|

Minimum Thickness for Slabs Without Interior Beams

(longest clear span divided by value of given)

|

|

without drop panels

|

with drop panels

|

|

|

Exterior panels

(in)

|

Interior

panels

(in)

|

Exterior panels

(in)

|

Interior

panels

(in)

|

|

yield

strength

(psi)

|

without

edge

beams

|

with

edge

beams

|

|

without

edge

beams

|

with

edge

beams

|

|

|

40,000

|

33

|

36

|

36

|

36

|

40

|

40

|

|

60,000

|

30

|

33

|

33

|

33

|

36

|

36

|

|

75,000

|

28

|

31

|

31

|

31

|

34

|

34

|

|

|

For slabs without beams or whose beams are only placed between exterior columns

(i.e., slabs without beams between interior supports), minimum thickness is specified

as the largest clear span (face-to-face of supports) divided by the values listed

in the table above. for the values in the table to be useful, drop panels

must project below the slab at least 1/4 of the slab thickness beyond the drop and

must extend in each direction at least 1/6 the length of the corresponding span.

The thickness of the slab without drop panels may not be less than 5 in. Slabs

with drop panels may not be less than 4 in thick.

|

For the purpose of calculating minimum thickness in slabs with beams between interior

supports, there are three possibilities. For am <= 0.2, the minimum thickness

is computed neglecting the beams. For 0.2 < am <= 2.0, the minimum thickness

is given in the equation below where B is the ratio of clear spans in the long-to-short

directions.

h = ln(0.8 + fy/200,000)/(36 + 5B(am - 0.2)) >= 5 in

for am > 2.0, the minimum thickness is

h = ln(0.8 + fy/200,000)/(36 + 9B) >= 3.5 in

When the stiffness ratio a of the edge beam is less than 0.8, the minimum thickness

in the edge panel shall be at least 10% larger than the value obtained in the equations

above.

|