|

Spread Footing Design Process: |

|

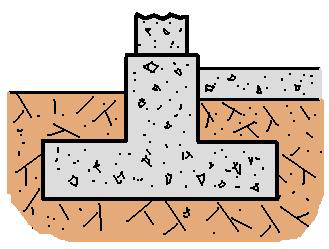

The design of spread footings is somewhat simplified when you follow the step by

step process below. The purpose of a foundation is to distribute the loads of the

building or structure to the soil in such a way that the soil will bear the load.

In layman’s terms the purpose of the foundation and in this case the spread footing

is to distribute the load to the soil without exceeding the bearing capacity of

the soil. Hence the very first step in the process of designing the spread footing

is to calculate the area required to support the vertical load on the soil. The

following is a simplified step by step process for the design of a spread footing:

|

|

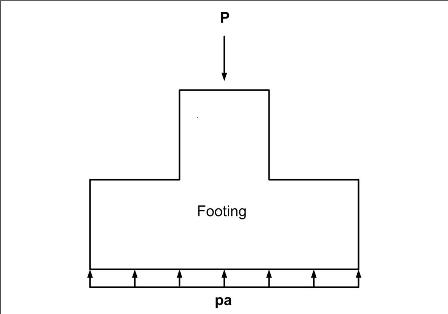

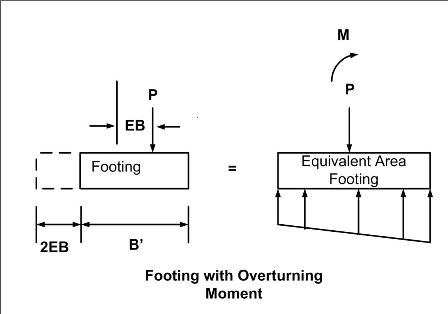

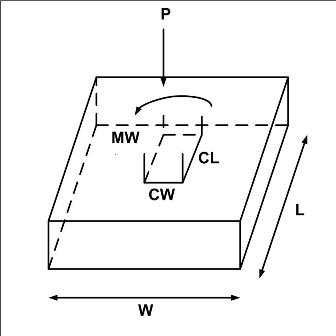

1. Determine the

area required for a trial design section and choose the initial dimensions,

(i.e., width, B and length, L), based on the allowable soil pressure or bearing

capacity. If it is necessary for the load on the footing to be off center, insure

that the load is centered on one axis, (preferably the long axis), and on the middle

third of the overall footing area along the other axis. Size the overall footing

so that the reduced area due to the eccentricity, E, is equivalent to the area required

for the trial design section. The reduced area places the equivalent force at the

centroid of a reduced area.

|

|

|

|

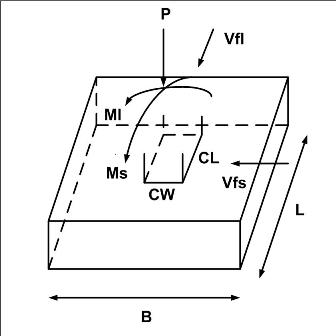

For a non-centered load the eccentricity is: EB = MB/P; EL = ML/P

The equivalent area dimensions are: L’ = L - 2EL; B’ = B - 2EB

With the equivalent area: A’ = L’B’

|

|

|

2. Check the maximum and minimum

soil pressures resulting from an applied moment load. Either a moment load

from a lateral load on the column or from the eccentricity from the off center load

on the footing. If there is no moment load ML then:

|

|

ppmax, pmin =(P/BL)( 1+or- 6EB/B)

|

|

|

3. Adjust the area if the minimum soil pressure is negative, or if the maximum exceeds

the allowable soil pressure. A negative minimum soil pressure means that the soil

pressure resultant is not distributed over the entire area of the footing. Even

if the maximum pressure is below the soil bearing capacity, this situation could

cause other problems, such as uneven long term settlement issues, as well as the

area is not economical.

|

|

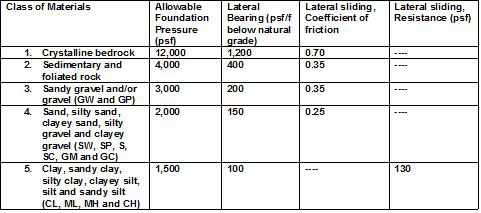

4. If there is an applied shear load against the footing, check the footing’s resistance

to sliding as in the design of retaining walls, (see retaining wall design).

|

|

|

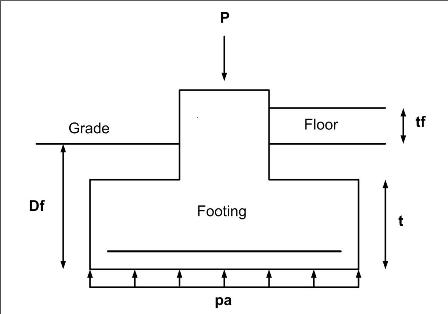

5. Validate the trial design section

area accounting for soil surcharges from adjacent floor loads etc. Always

use normal weight concrete. In my experience there has never been any reason for

light weight concrete in a foundation, and the additional weight is used to add

ballast to the structure against uplift loads. If there is serious uplift

loading, check uplift resistance of the

footing.

|

|

6. Next begin with trial section thickness, depth to steel (d) and check the 1-way shear and

2-way (punching) shear. If the applied load is a vertical load only, 2-way

shear always rules. As stated above normal weight concrete is always used.

|

|

|

7. Design the flexural steel.

Rather than design the steel for the flexural stress in each section and each direction,

which is how many methods and codes allow and many text books will design it. It

is my experience that the construction cost of purchasing, stocking and tying several

different sizes of steel reinforcement negates the savings realized by the smaller

steel cross sections and differing spacing, therefore I recommend determining the

area of steel required for the critical section and then specifying the same size

and spacing for the spread footing throughout and in both directions.

|

|

8. Check the development length

of the flexural reinforcement.

|

|

9. Check the column dowel size

and development length.

|