|

|

Steel Tension Design Problem 1 - Calculate the capacity of a tension member:

|

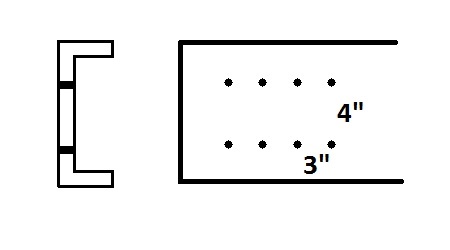

A C15x50 channel is used as a tension member. Steel grade is A36 (Fy = 36 ksi, Fu = 58 ksi).

The member is connected using two lines of 4 - 3/4 in diameter bolts in the web.

The bolts are spaced 3 inches apart and the distance from outside bolt to outside bolt is 9 inches.

Determine the member capacity in tension.

|

|

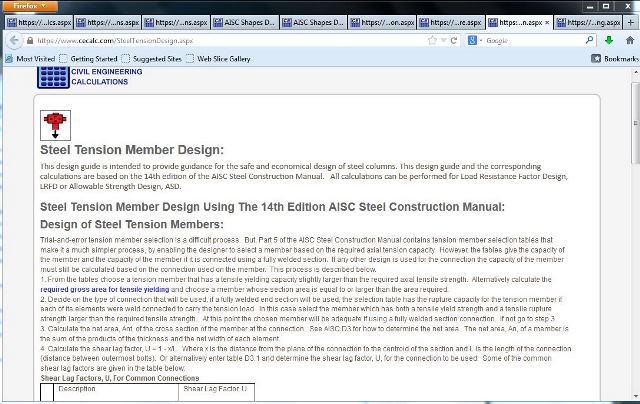

1. From the steel tension submenu open the steel tension design guide, SteelTensionDesign.aspx. Read through the process for solving for the capacity of a steel tension member.

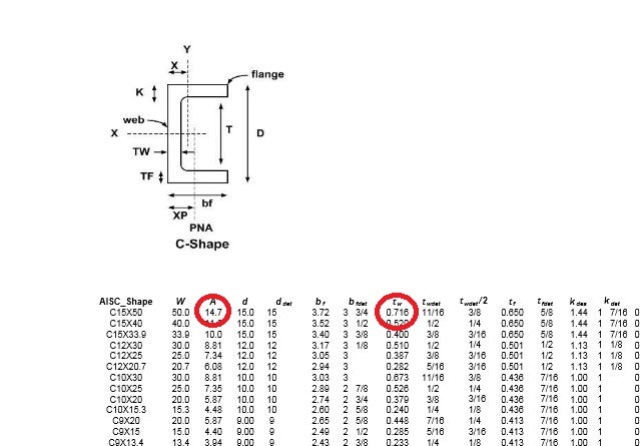

Then from the steel shape section properties submenu open the channel section properties table, CShapeTable.pdf.

|

|

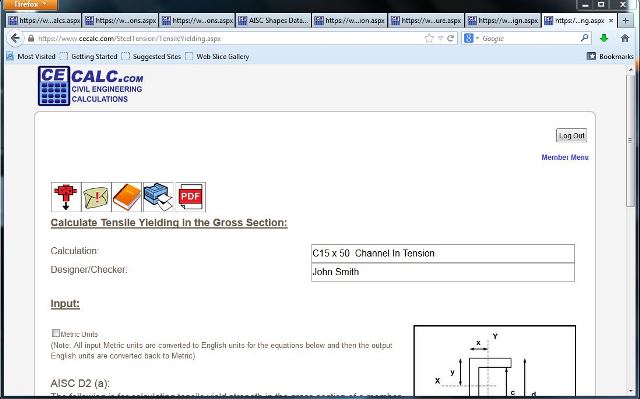

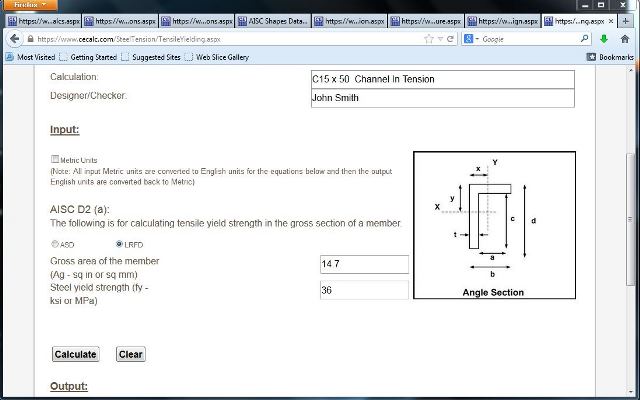

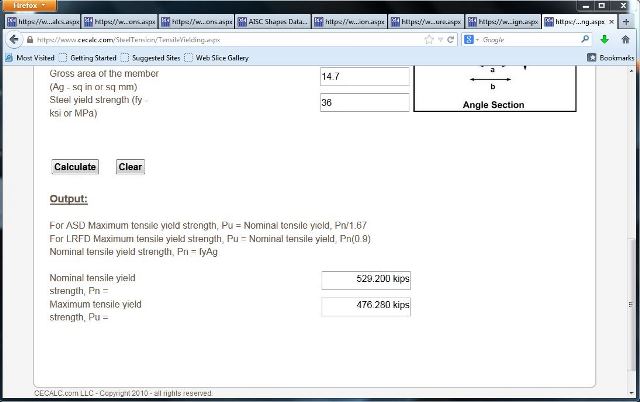

2. Next, determine the gross yield capacity. From the steel tension submenu open the tensile yielding calculation, TensileYielding.aspx. Input the "Title" of the calculation, the "Designer/Checker" information.

Reference the table and input the section area. Click on the "Calculate" button and read the results. The maximum tensile yield strength is 476.28 kips.

|

|

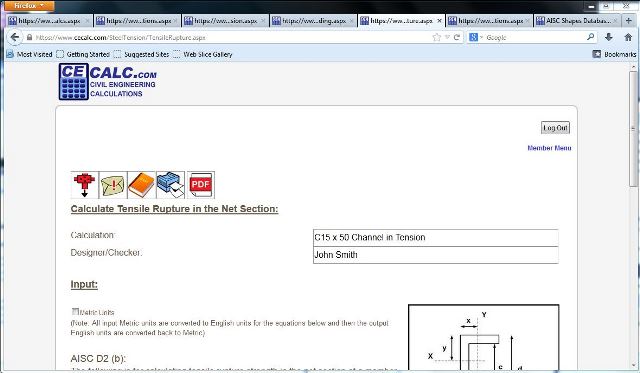

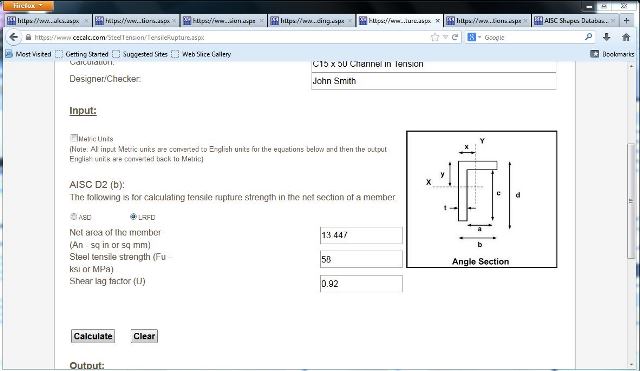

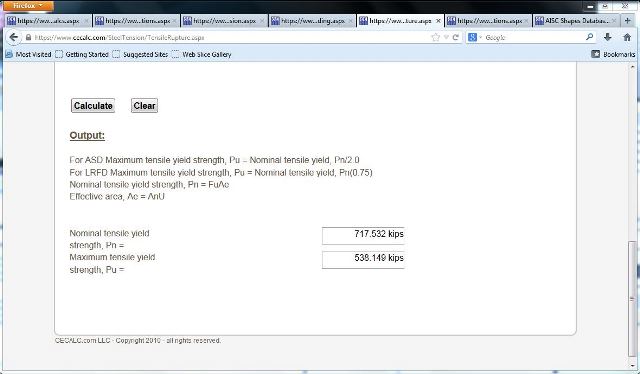

3. Next determine the tensile rupture yield strength in the net section. From the steel tension submenu open the tensile rupture calculation, TensileRupture.aspx. Input the "Title" of the calculation, the "Designer/Checker" information and the variables.

The net area, An = 14.7 - 2 x 7/8 x 0.716 = 13.447 and the shear lag factor, U = 1-x/L = 1 - 0.716/9 = 0.92. Click on the "Calculate" button and read the results. The maximum yield strength by tensile rupture is 538.149 kips.

|

|

4. Summary

|

The tensile yield strength in the gross area is 476.28 kips. The tensile rupture strength in the net section area is 538.149 kips.

The tensile yield strength of the gross area governs so the capicity of the member in tension is 476.28 kips.

|

|

|